hardness test of aggregate|sound test for coarse aggregates : supplier In order to obtain accurate results with the Windsor Probe System, it is necessary to know the hardness of the coarse aggregate, as expressed in “Mohs.”. This test method covers the . The Atrium Hotel, A Top Hotel in San Bruno, CA, Located in the Heart of the Bay Area. Our hotel near the San Francisco International Airport and Highway 101 is a great home base for exploring San Francisco and the .

{plog:ftitle_list}

webRetro Boobs Porn Videos. All HD 4K. Trending Newest Best Videos Quality FPS Duration Production. Retro. Boobs. Retro Big Boobs. German Retro. Retro Full Movie. Retro .

polarimeter performance qualification

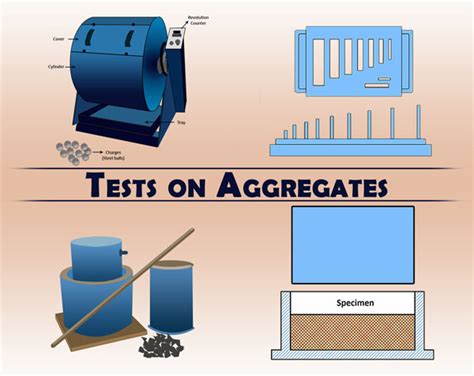

Hardness property of aggregate is determined by conducting abrasion test. Los Angeles abrasion testing machine is used to conduct this test. For this test, .In this blog, we’ll focus on construction materials tests that measure aggregate characteristics like soundness, toughness, and durability. The size, shape, density, and texture of construction aggregates are just as important and will .

In order to obtain accurate results with the Windsor Probe System, it is necessary to know the hardness of the coarse aggregate, as expressed in “Mohs.”. This test method covers the . The standard method of test for Soundness of Aggregates by Freezing and Thawing, outlined in AASHTO T 103, determines the resistance of an aggregate to . The hardness of aggregates is assessed through the abrasion test, employing a Los Angeles abrasion testing machine. This test provides valuable insights into the ability of .This Bulletin describes types of aggregates normally used in concrete, aggregate properties affecting performance of the concrete, tests used to measure aggregate properties, and .

polarimeter perkin elmer

Understanding the Schmidt Rebound Hardness Test. The Schmidt rebound hardness test on rock is a widely recognized method for rapidly gauging the surface hardness of rock formations, offering valuable insights into their . Abrasion test on aggregate indicates the hardness of aggregate. It shows the ability of aggregate to resist wear and tear. (b) Recommended Result of Abrasion Test: Abrasion value of aggregate should .The Mohs mineral hardness test is a crucial test for determining aggregate hardness. The Mohs test involves analyzing a mineral’s resistance to scratching effects from ten different mineral samples, which allows you to determine the . Experimental determination of hardness of coarse aggregates. For coarse aggregates, the hardness can be assessed through Los Angeles Abrasion Value (LAAV) Test. This test gives the percentage wear of .

Place each sample in separate containers for the test (the aggregate can be placed in 3 to 5 layers of cheesecloth) Immerse the samples in the prepared solution of sodium sulfate or magnesium sulfate for 16 to 18 hours. Cover the containers to reduce evaporation and prevent contamination and maintain the temperature between 20.3 to 21.9°C for .For testing hardness of aggregate following three methods can be used: (a) Deval Attrition test. (b) Dorry abrasion test. ADVERTISEMENTS: (c) Los Angeles test. (a) Deval Attrition Test: This test has been covered by IS 2386 Part (IV)-1963. In this test particles of known weight are subjected to wear in an iron cylinder rotated 10,000 (ten .

Hardness; Aggregates used in road construction especially in the top surface course should be hard enough to withstand the abrasion and attrition due to moving vehicle load. Aggregate abrasion value for the bituminous wearing surface in the road is limited to 30%. . Soundness test for aggregate can be conducted by submerging the sample into .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below. The point load test apparatus and procedure enables economical testing of core or lump rock samples in either a field or laboratory setting. In order to estimate uniaxial compressive strength .Abstract. The standard superficial Rockwell 15Y hardness test has been adapted for use on concrete. Hardness measurements were made on the mortar regions between the coarse aggregate pieces. A correlation between this hardness and the concrete's compressive strength was developed. For 7.5- by 15-cm (3- by 6-in.) cylinders, it is Rockwell 15Y hardness = 73.5 .

Understanding the MOHS hardness test. The Mohs Hardness Scale is a widely used method for determining the relative hardness of minerals and other objects. This scale consists of ten reference minerals numbered 1 through 10, which range from a very soft mineral (talc) to a very hard mineral (diamond). The abrasion test assesses the hardness of aggregates, providing essential information about their resistance to wear and tear. This data is crucial for predicting the long-term durability of pavements. 3. Impact Test on Aggregates. Testing Procedure: Sample Preparation: Similar to other tests, the aggregate sample is prepared by sieving and .

Section snippets Experimental programme and procedure. To study the effect of old mortar on the recycled aggregate (RA) surface in the recycled aggregate concrete (RAC), properties were determined by experimental approaches: the failure shape of recycled aggregate and recycled aggregate concrete was measured by both compressive and tensile .

Hardness property of aggregate is determined by conducting abrasion test. Los Angeles abrasion testing machine is used to conduct this test. . In this test the aggregates are coated with bitumen and dried. After drying they are immersed in water at 40 o c for about 24 hours. Stripping value of aggregate should not exceed 5%.In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .We would like to show you a description here but the site won’t allow us.Los Angeles test is commonly used to evaluate the hardness of aggregates. The test has more acceptability because the resistance to abrasion and impact is determined simultaneously. Depending upon the value, the suitability of aggregates for different road constructions can be judged as per IRC specifications as given:

Abrasion test is carried out to test the hardness property of aggregates and to decide whether they are suitable for different pavement construction works. Los Angeles abrasion test is a preferred one for carrying out the hardness . Request PDF | Study on interfacial transition zone properties of recycled aggregate by micro-hardness test | This study was undertaken using two experimental approaches for analyzing the influence .Core diameters should be a minimum of two times the maximum aggregate size. The preferred core diameter for a compressive strength specimen is three times the maximum aggregate size of the concrete (see section 7 of ASTM C 42). Length-to-diameter ratios are ideally 2:1, but this test method provides correction factors for ratios as low as 1:1.

The rock type determines the hardness, durability, and potential chemical reactivity of the rock when mixed with cement to make concrete. . Testing Aggregate in Bituminous Applications: AASHTO T-165: ASTM D 1075: Effect of Water on Cohesion of Compacted Bituminous Mixtures: AASHTO T-182:The ASTM C39 test standard for compressive strength of concrete cylinders requires numerous checks for dimensions of the concrete cylinders and alignment during testing. The manual instructs and illustrates acceptable practices to properly perform these measurements. C39 gives basic requirements for concrete compression testing machines, but the manual provides non .

Aggregate test is a process of performing certain tests on aggregates, as it is one of the main components of concrete. it is necessary to have certain checks for the physical properties, quality, and suitability of aggregates for specific applications in construction projects. . This test is essential for assessing the toughness or hardness .ASTM C29 – Test Method for Bulk Density (Unit Weight) and Void in Aggregates; ASTM C33 – Standard Specification for Concrete Aggregates; ASTM C40 – Organic Impurities in Fine Aggregate for Concrete; ASTM C88 – Standard Practice for Sampling Aggregates by the use of Sodium Sulfate or Magnesium Sulfate. Please watch: "Bulk density of aggregate coarse or fine as per IS 2386, hardness test of aggregate" https://www.youtube.com/watch?v=NM-i_yq8VpY-~-~~-~~~-~~-~.

In recent years, the Micro-Deval Test has gained acceptance and popularity as an economical and accurate procedure for aggregate abrasion testing. The basis for this method was developed in France during the 1960s and provides a measure of toughness, abrasion resistance, and durability of mineral aggregates as they are ground with steel balls .Hardness ˜ Hardness is the aggregate’s resistance to abrasion (wear) . Mass of intact particles left after test 3,891 g (1 pound = 454 grams) .

tests for aggregates

Aggregate Crushing Value/Strength Test : This test gives the Aggregates Crushing Value (ACV), which is an index of crushing strength of aggregates. The apparatus used for this test is Compression Testing Machine / Universal Testing Machine. A sample of aggregates in surface dry condition, which pass through the 12.5 mm sieve and are retained .

testing aggregates in construction

sound test for coarse aggregates

Acompanhe o Magic! Acompanhe o Magic! Receba ofertas e.

hardness test of aggregate|sound test for coarse aggregates